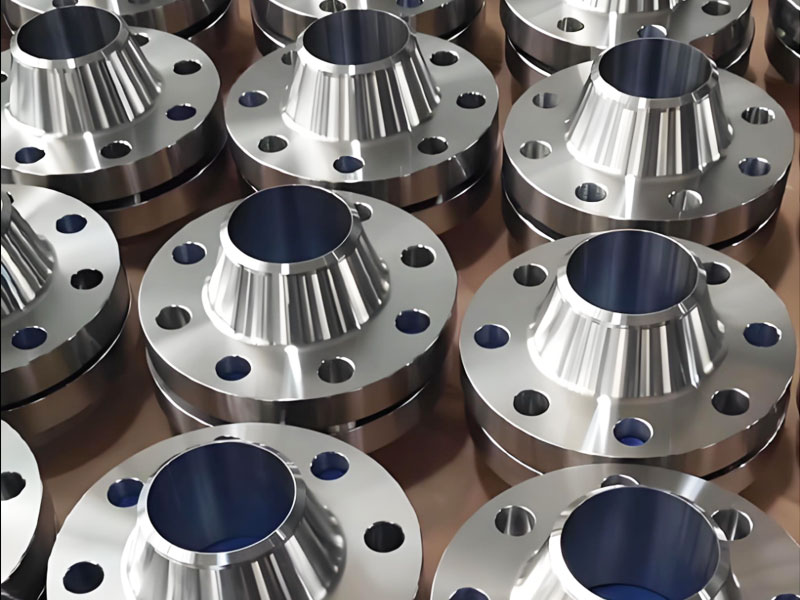

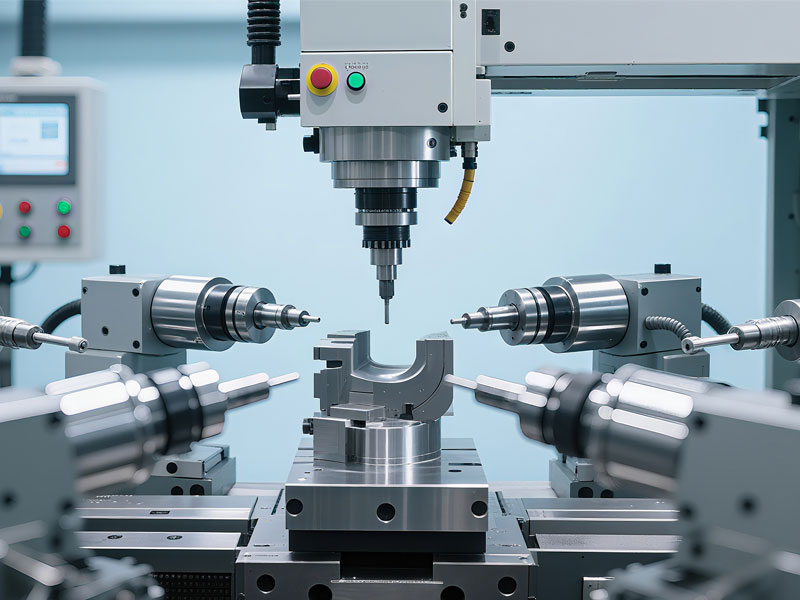

HLC Sheet Metal Factory delivers high-precision CNC machining solutions for a wide range of industries, including medical devices, orthopedic, aerospace and telecommunications. Our expertise in tight-tolerance machining, complex geometries and critical materials makes us a trusted partner for customers that demand accuracy, consistency, and quality.

CNC precision machining involves a variety of subtractive manufacturing processes, such as cutting, grinding, and drilling, with specialized tools and computer numerical control (CNC) machines. These processes are used to create intricate and complex geometries, with the tightest tolerances, as required by demanding industries including medical devices as well as aerospace, automotive & robotics.

HLC Sheet Metal Factory, modern precision machining services achieve much tighter tolerances than standard CNC precision machining. While standard CNC precision machining produces tolerances of about 0.12 to 0.2 mm, our precision machining can achieve tolerances as close as 0.0001 in (0.0025 mm). HLC Sheet Metal Factory facility brings state-of-the-art technology and expert craftsmanship together to meet the growing demands of industries that require meticulous accuracy and durability.