Surface treatment refers to modifying the surface of a material, often metal, to enhance its properties, such as corrosion resistance, durability, adhesion, and appearance. In this guide, we provide a technical overview of 15 essential metal surface treatment methods and learn how these processes extend product lifespans and reduce maintenance costs.

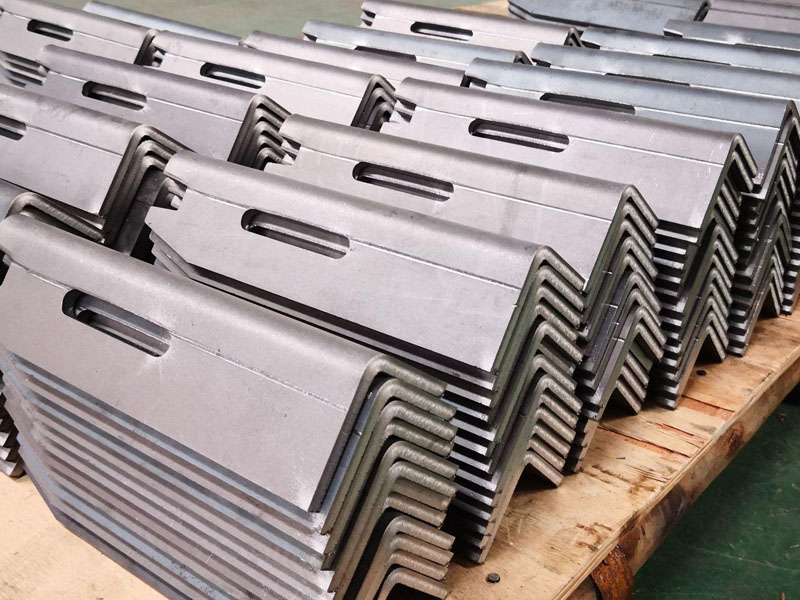

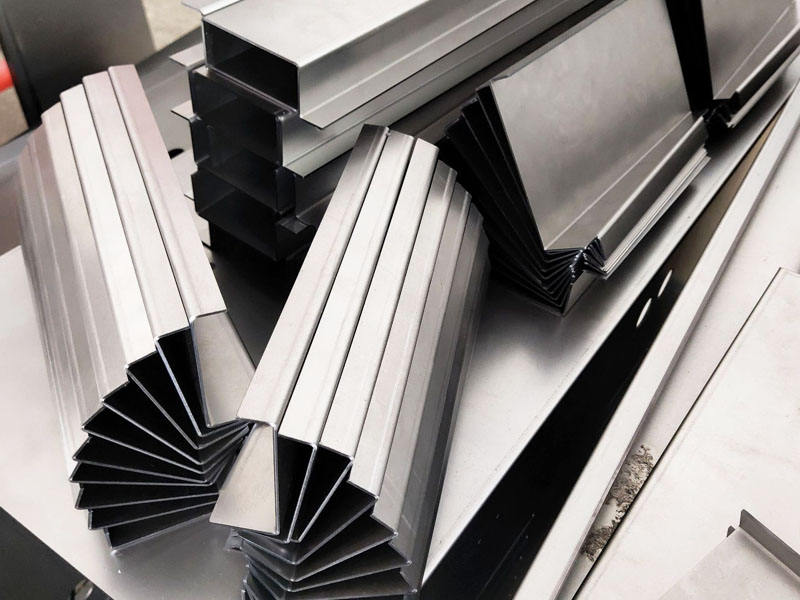

1. Rough Finish

Standard surface means that no further surface treatment is required for the original metal surface of the final part. This means that during the manufacturing process, the metal material’s initial state already possesses the required surface smoothness and other characteristic requirements. Stainless steel 304 is a common example. Due to its smooth surface and excellent corrosion resistance, stainless steel 304 can be used without further surface treatment. When the natural state of the metal material matches the project specifications, the standard surface becomes a practical and cost-effective choice.

2. Phosphating Treatment

Phosphating is a chemical process that creates a protective phosphate coating on metal surfaces. It involves a chemical reaction between the metal workpiece and a phosphate solution, resulting in the formation of a crystalline layer. This layer enhances adhesion and provides excellent corrosion resistance.Phosphating has different variations, with zinc phosphate, manganese phosphate, and iron phosphate being the main categories. It is widely used in the automotive industry for coating car bodies and chassis, as well as in the construction of agricultural machinery.

3. Electroplating Process

Electroplating is the process of depositing a layer of metal onto a metal object using an electric current. This layer of metal, often customized to meet specific requirements such as nickel, zinc, gold, or chromium, acts like a protective “coat” for the metal, enhancing its ability to resist corrosion, wear, and the test of time.Steel, for instance, often undergoes electroplating to provide protection against rust. Similarly, the jewelry industry uses electroplating for silver-coated jewelry. In the electronics sector, it’s also employed to enhance the conductivity of metal components.

4. Electroless Plating

Electroless Plating, also called chemical plating, traditionally classified as a subset of electroplating, represents a distinctive branch within the realm of electroplating. Its fundamental difference lies in the fact that chemical plating, doesn’t rely on an external electrical current and the presence of an anode.Chemical plating’s core principle centers around a self-catalyzing reaction that occurs on the surface of the workpiece, where the plating layer induces its own deposition. One of the key advantages of chemical plating is its ability to provide even and consistent coatings, a challenge for traditional electroplating when dealing with complex shapes or internal surfaces.

5. Passivation Treatment

Passivation, also known as chromate treatment, is a process that involves immersing metal in a solution containing substances like nitrate, chromate, and dichromate. This process forms an exceptionally thin, compact, and firmly adhering passivation film on the metal’s surface. Importantly, this film is virtually invisible and doesn’t alter the workpiece’s appearance or thickness.After the stainless steel workpiece is cut, there are usually iron filings, steel particles, and coolant residue on the surface, which can cause stains and rust. Therefore, it is necessary to degrease and remove oil, followed by nitric acid cleaning, to remove the iron filings and steel particles and perform passivation.

6. Anodizing

Anodizing employs an electrolytic method to form an oxide film on the surface of a metal. Its most striking feature is the ability to impart vibrant colors to the metal. Non-ferrous metals and their alloys, such as aluminum and magnesium, can undergo anodizing. To address limitations in surface hardness and wear resistance, aluminum alloys are the most common materials subjected to anodizing.

7. Alodine Surface Treatment

Alodine surface treatment is a chemical process used to enhance the corrosion resistance of aluminum surfaces. It forms a protective film (0.4-5 micrometers) which, despite having only 20% of the wear resistance of an anodized film, exhibits superior flexibility and adhesion, especially with paints. As a result of the Alodine treatment, the color of the metal surface can be altered, often resulting in a subtle yellow or gold tint. It is important to exercise caution during the application of Alodine solution due to its toxic nature.

8. Powder Coating

By leveraging electrostatic forces, it precisely adheres pigmented powder coatings to the surfaces of workpieces. Subsequently, a curing process in an oven ensures the creation of a robust protective coating. This method is invaluable for safeguarding metal products from corrosion and physical harm while offering a broad color palette and customizable surface textures. It excels in applications involving outdoor exposure and high-temperature environments, making it a top choice for industries such as automotive, architecture, and more.

9. Sandblasting Process

Sandblasting is a destructive processing method. Using compressed air as the driving force, abrasive material particles are propelled at high speed onto the surface of the workpiece for treatment. Due to the impact and cutting action of the abrasives on the workpiece surface, the workpiece’s surface achieves a certain level of cleanliness and various degrees of roughness. Due to the adjustability of the type, size, and pressure of abrasive particles, sandblasting treatment allows for the flexibility to choose among various levels of surface roughness, other processes cannot achieve this.

10. Beading Blasting

Bead blasting and sandblasting share a similar underlying process of using compressed air to propel abrasive materials onto a metal surface. However, they differ in the type of abrasive materials used and the intended results. Bead Blasting: This method uses spherical abrasive materials such as glass beads or ceramic beads. These beads are generally gentler and create a smoother surface texture. while sandblasting employs sharp-edged abrasives like sand.

11. Polishing

The primary objective of polishing is to reduce surface roughness and enhance the appearance of a material’s surface, making it shinier and more aesthetically pleasing. This process does not significantly affect the dimensional accuracy or geometric precision of the workpiece. Mechanical Polishing is one of the most traditional and commonly used methods of polishing. This method typically involves operators manually using materials such as wool wheels, sandpaper, or other abrasive substances to polish the surface of the workpiece.

12. Electropolishing

Electrochemical Polishing stands as a distinct category within the realm of polishing, and it’s worth emphasizing that, despite sharing the same objective, electrochemical polishing is not constrained by the shape or geometric features of the workpiece. In electrochemical polishing, the workpiece is immersed in an electrolyte solution, and an electric current is applied to achieve the desired surface finish. It’s important to note that if the surface is too rough, direct electrochemical polishing may not be suitable, and preliminary mechanical polishing may be required.

13. Etching Process

Etching is a precise and controlled process that involves the removal of materials from the surface of metal through chemical methods. Etching offers high accuracy and is often used to create intricate designs, patterns, or labels on metal surfaces. Especially for the processing of electronic components such as thin films, etching enables the creation of tiny and precise mesh patterns. From traditional metalworking to advanced semiconductor manufacturing, etching techniques are indispensable.

14. Acid Pickling Treatment

Acid pickling is primarily used to remove oxides and rust from the surface of steel. The most commonly used acids for this purpose are sulfuric acid and hydrochloric acid, but they are difficult to handle due to their corrosiveness and not suitable for all types of stee. Some alloys and high-carbon steels can react with hydrogen in acids, leading to embrittlement and the formation of cracks. Acid pickling provides a clean and scale-free surface, essential for achieving consistent quality in subsequent processes such as welding or plating.

15. Heat Treatment

Heat treatment is a process used to enhance the mechanical properties of metals by heating them to a specific temperature and then cooling them. Unlike other surface treatments that focus on altering the outer layers of metal, heat treatment modifies the internal structure of the metal to achieve the desired mechanical properties. This technique is employed to improve hardness, strength, ductility, and other characteristics. By carefully controlling the heating and cooling parameters, metal components can be tailored to meet the required performance criteria.

Choosing the right sheet metal finishing process depends on various factors, including the material, intended use, and desired properties of the finished product. Here are some key considerations to guide your decision: Each surface treatment serves specific functions, whether it’s improving the material’s resistance to wear, enhancing its aesthetic quality, or making it more suitable for specialized environments.

HLC Sheet Metal Factory with over 20 years of expertise in metal manufacturing, is well-equipped to meet a wide range of surface treatment needs. From design to finished product, HLC Sheet Metal Factory offers comprehensive, one-stop services.