In today’s competitive landscape, where innovation cycles accelerate and quality is non-negotiable, choosing the right CNC machining manufacturer is critical. Look beyond the machine shop; partner with a powerhouse of precision manufacturing, built on robust capabilities, cutting-edge technology, and an unwavering commitment to your project’s triumph. Here’s why we stand as your ideal solution.

Unmatched Manufacturing Muscle & Technical Prowess:

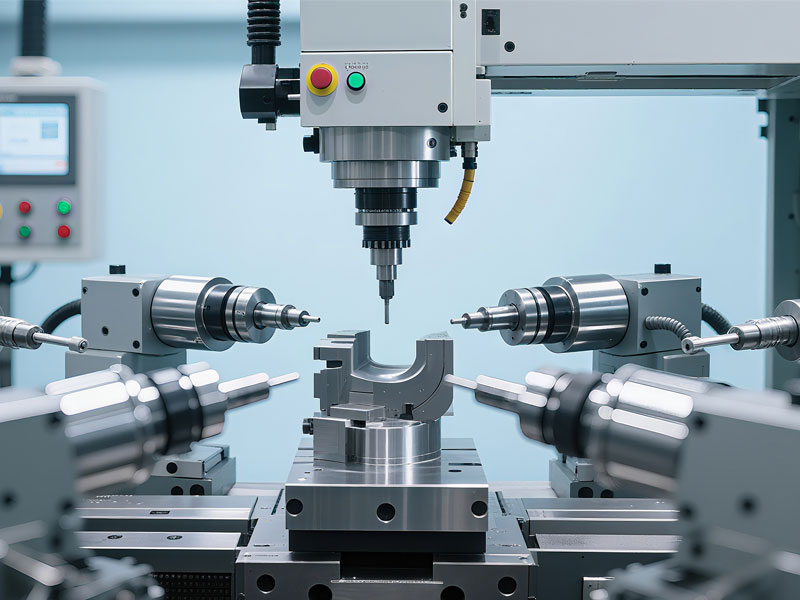

Our foundation is a state-of-the-art facility humming with a comprehensive fleet of advanced CNC machinery. From high-speed 3-axis mills tackling intricate components to sophisticated 5-axis machining centers producing complex, contoured geometries with unparalleled accuracy, we possess the breadth and depth to handle diverse challenges. Complementing our mills, our precision CNC turning centers, including multi-axis lathes and Swiss-types, deliver exceptional results for rotational parts, ensuring dimensional perfection and superior surface finishes. This extensive in-house capability translates to flexibility, scalability, and complete control over your production timeline.

Mastery of Advanced Processes & Materials:

We don’t just run machines; we master processes. Our engineering team possesses deep expertise in optimizing machining strategies for a vast material portfolio – aerospace-grade aluminum and titanium, robust stainless steels, engineering plastics like PEEK and Ultem, and specialized alloys. We leverage advanced techniques such as high-speed machining (HSM) for efficiency, hard milling for hardened steels, and micro-machining for delicate, miniature components. This mastery ensures optimal performance, material integrity, and cost-effectiveness for every unique application, whether it’s a critical aerospace bracket, a life-saving medical implant, or a high-volume automotive sensor.

Your Design & Engineering Ally:

Innovation thrives on collaboration. Our seasoned design and engineering team isn’t just here to execute prints; they’re your proactive partners. Leveraging advanced CAD/CAM software and decades of practical manufacturing experience, they excel at Design for Manufacturability (DFM) analysis. We identify potential production hurdles early, suggest optimizations for cost reduction and enhanced functionality, and ensure your brilliant concepts translate seamlessly into manufacturable, high-performance parts. From prototype refinement to complex production runs, our engineers are dedicated to making your vision a manufacturable reality.

The Uncompromising Pursuit of Flawless Quality:

“Good enough” is never in our vocabulary. We embed rigorous quality control at every stage. Our certified metrology lab, equipped with advanced CMMs, optical comparators, surface testers, and precision gauging, provides meticulous inspection and validation. This systematic approach guarantees that every component leaving our facility meets or exceeds your exacting specifications, delivering consistent reliability you can depend on.

Speed You Can Count On:

We understand that time is a critical competitive edge. Our streamlined workflow, powered by efficient production planning, optimized tooling strategies, and integrated automation where applicable, minimizes lead times without sacrificing quality. We leverage our extensive in-house capabilities to avoid outsourcing delays. From rapid prototyping to bridge production and full-scale manufacturing, we deliver with the speed and predictability your projects demand – often turning around complex parts in weeks, not months.

Exceptional Value, Optimized Costs:

True value isn’t just the lowest price; it’s the optimal balance of superior quality, reliable delivery, and competitive cost. Our commitment to operational efficiency, bulk material sourcing, advanced machining optimization to reduce cycle times, and minimized waste through expert programming allows us to offer highly competitive pricing. We provide transparent quotes and work closely with you to identify cost-saving opportunities without compromising the integrity of your part.

Partner for Precision Progress:

We are more than a supplier; we are your dedicated partner in precision manufacturing. Leverage our formidable manufacturing strength, advanced technical expertise, collaborative engineering support, uncompromising quality, rapid turnaround, and exceptional value to bring your most ambitious projects to life with confidence.

Ready to experience the difference precision partnership makes? Contact us today for a quote and discover how we can accelerate your success.