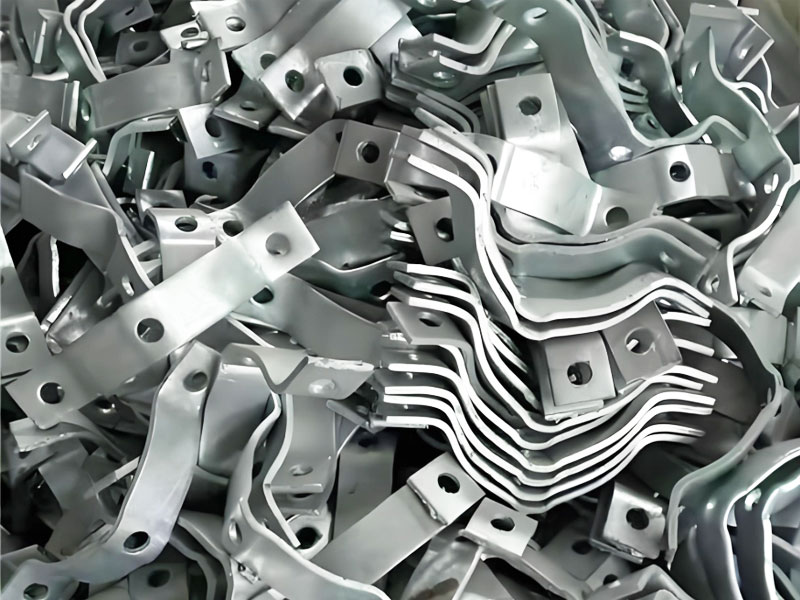

Precision Sheet Metal Fabrication for Energy Storage Enclosures

In the race toward a sustainable energy future, robust, reliable Energy Storage Enclosures are non-negotiable. At HLC Sheet Metal Factory, we combine advanced sheet metal fabrication mastery with industry-specific expertise to deliver enclosures that protect critical battery systems—ensuring safety, performance, and longevity. Advanced Manufacturing Capabilities for Superior Enclosures Our factory is equipped with state-of-the-art sheet […]